Dr. Shunichi Igarashi has surprised even himself with his line of Super Reinforcement with Flexibility (SRF) technology. SRF basically involves wrapping the columns and walls of building in adhesive strips.

The idea of gluing fabric on a building to protect it from the sheer force of an earthquake doesn’t sound very comforting. However, when Dr. Igarashi’s SRF was put to the test in the Great Tohoku Earthquake on 11 March, 2011, it passed with flying colors.

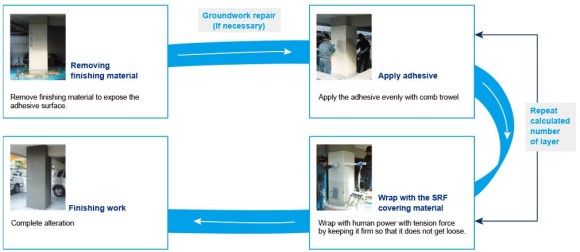

The process of SRF is actually as simple as it sounds. Just expose the surface of a pillar, apply a specially designed solvent-free adhesive and wrap the strips of fabric tightly around the column. Repeat if necessary, and your building becomes stronger.

It’s so simple that organizations that are too important to close down such as hospitals and RocketNews24 Towers can continue functioning at full capacity while the renovation is being done. The adhesive has no odors or fumes and the process is quiet.

Dr. Igarashi came up with the idea while in Turkey. He had worked there before but immediately returned following the 1999 İzmit Earthquake. He and a group of students inspected the remaining building and determined those fit for use.

Unfortunately, a few months later, an almost equally strong aftershock hit killing his students when their dormitory collapsed.

Dr. Igarashi was devastated by this and remained holed up in his hotel room. Then one morning he began to feel an earthquake. As he was bracing himself he saw a column in front of him that was wavering but undamaged by the quake. It was wrapped in a white bandage. Then he awoke from his dream.

His initial thought was that reinforced concrete is like a body. The iron bars are like the skeleton and the concrete is like flesh. Together they are strong but if one part begins to fail then the structure quickly comes undone.

In that sense taping up pillars in a building would be just like an athlete taping up their arms, legs, etc. Covering reinforcement has already been done with steel which does improve strength.

However, the rigid strength of the steel transferred the strain of the vibrations to the uncovered areas such as joints. This can still make the overall structure highly dangerous following a quake.

The bandages of SRF can withstand 16 tons of strength per 4mm layer but bend with the concrete just enough to absorb the energy and prevent dangerous cracking.

Once the design was complete, Dr. Igarashi installed SRF in various buildings across Japan including four in Sendai City.

■ The Sakurano Department Store was reinforced with SRF in 2010. It was also one of the earliest businesses to reopen after 11 March. It was functioning less than a month after.

■ Another small store in Sendai could remain in business after the earthquake of 2011 while other stores around it either had to be closed or collapsed.

■ An elementary school was reinforced in 2007 and could reopen earlier than neighboring schools.

■ Owners of an apartment building which was deemed up to code for earthquake prevention decided to invest in some extra security with SRF. Following the earthquake even the tiles of the building remained in place.

These results were even surprising to the makers of the material. It was later determined that in addition to supporting the reinforced concrete, SRF actually helped to dampen the seismic waves of the earthquake giving it another level of protection.

On top of that, some companies have reported that the strips also act as insulation, lowering the utility costs for heating and cooling. It can also be used on wooden structures.

It’s a job well done for Dr. Igarashi and his team and one he says he will continue to improve on. Johnson & Johnson should also thank him for putting a positive spin on “Band-Aid solution.”

Source: SRF (English) via Nikkei Business Online (Japanese)

▼ A video demonstrating how easy it is to install SRF

Single “Hebel Haus” is the only structure to defy the flooding of Japan’s Angry Demon River

Single “Hebel Haus” is the only structure to defy the flooding of Japan’s Angry Demon River 3-D printing a house in less than 24 hours — Japanese company meets its goal

3-D printing a house in less than 24 hours — Japanese company meets its goal Japanese entertainer shakes fresh cream to make butter… in the most unusual way【Video】

Japanese entertainer shakes fresh cream to make butter… in the most unusual way【Video】 97 percent of Kumamoto convenience stores open for business just three days after major quakes

97 percent of Kumamoto convenience stores open for business just three days after major quakes Five years on, Google Maps updates images of areas affected by 2011 earthquake and tsunami

Five years on, Google Maps updates images of areas affected by 2011 earthquake and tsunami Red light district sushi restaurant in Tokyo shows us just how wrong we were about it

Red light district sushi restaurant in Tokyo shows us just how wrong we were about it Sandwiches fit for a sumo served up in Osaka【Taste Test】

Sandwiches fit for a sumo served up in Osaka【Taste Test】 Tokyo Tsukiji fish market site to be redeveloped with 50,000-seat stadium, hotel, shopping center

Tokyo Tsukiji fish market site to be redeveloped with 50,000-seat stadium, hotel, shopping center McDonald’s new Happy Meals offer up cute and practical Sanrio lifestyle goods

McDonald’s new Happy Meals offer up cute and practical Sanrio lifestyle goods French Fries Bread in Tokyo’s Shibuya becomes a hit on social media

French Fries Bread in Tokyo’s Shibuya becomes a hit on social media Pokémon Sleep camping suite and guestrooms coming to Tokyo Hyatt along with giant Snorlax burgers

Pokémon Sleep camping suite and guestrooms coming to Tokyo Hyatt along with giant Snorlax burgers Japanese ramen restaurants under pressure from new yen banknotes

Japanese ramen restaurants under pressure from new yen banknotes Akihabara pop-up shop sells goods made by Japanese prison inmates

Akihabara pop-up shop sells goods made by Japanese prison inmates Anime girl English teacher Ellen-sensei becomes VTuber/VVTUber and NFT

Anime girl English teacher Ellen-sensei becomes VTuber/VVTUber and NFT Beautiful Ghibli sealing wax kits let you create accessories and elegant letter decorations【Pics】

Beautiful Ghibli sealing wax kits let you create accessories and elegant letter decorations【Pics】 All-you-can-drink Starbucks and amazing views part of Tokyo’s new 170 meter-high sky lounge

All-you-can-drink Starbucks and amazing views part of Tokyo’s new 170 meter-high sky lounge More foreign tourists than ever before in history visited Japan last month

More foreign tourists than ever before in history visited Japan last month Studio Ghibli releases new action figures featuring Nausicaä of the Valley of the Wind characters

Studio Ghibli releases new action figures featuring Nausicaä of the Valley of the Wind characters New private rooms on Tokaido Shinkansen change the way we travel from Tokyo to Kyoto

New private rooms on Tokaido Shinkansen change the way we travel from Tokyo to Kyoto Starbucks reopens at Shibuya Scramble Crossing with new look and design concept

Starbucks reopens at Shibuya Scramble Crossing with new look and design concept Studio Ghibli glasses cases let anime characters keep an eye on your spectacles

Studio Ghibli glasses cases let anime characters keep an eye on your spectacles Studio Ghibli releases Kiki’s Delivery Service chocolate cake pouches in Japan

Studio Ghibli releases Kiki’s Delivery Service chocolate cake pouches in Japan New definition of “Japanese whiskey” goes into effect to prevent fakes from fooling overseas buyers

New definition of “Japanese whiskey” goes into effect to prevent fakes from fooling overseas buyers Our Japanese reporter visits Costco in the U.S., finds super American and very Japanese things

Our Japanese reporter visits Costco in the U.S., finds super American and very Japanese things Studio Ghibli unveils Mother’s Day gift set that captures the love in My Neighbour Totoro

Studio Ghibli unveils Mother’s Day gift set that captures the love in My Neighbour Totoro New Japanese KitKat flavour stars Sanrio characters, including Hello Kitty

New Japanese KitKat flavour stars Sanrio characters, including Hello Kitty New Pokémon cakes let you eat your way through Pikachu and all the Eevee evolutions

New Pokémon cakes let you eat your way through Pikachu and all the Eevee evolutions Disney princesses get official manga makeovers for Manga Princess Cafe opening in Tokyo

Disney princesses get official manga makeovers for Manga Princess Cafe opening in Tokyo Sales of Japan’s most convenient train ticket/shopping payment cards suspended indefinitely

Sales of Japan’s most convenient train ticket/shopping payment cards suspended indefinitely Sold-out Studio Ghibli desktop humidifiers are back so Totoro can help you through the dry season

Sold-out Studio Ghibli desktop humidifiers are back so Totoro can help you through the dry season Japanese government to make first change to romanization spelling rules since the 1950s

Japanese government to make first change to romanization spelling rules since the 1950s Ghibli founders Toshio Suzuki and Hayao Miyazaki contribute to Japanese whisky Totoro label design

Ghibli founders Toshio Suzuki and Hayao Miyazaki contribute to Japanese whisky Totoro label design Doraemon found buried at sea as scene from 1993 anime becomes real life【Photos】

Doraemon found buried at sea as scene from 1993 anime becomes real life【Photos】 Tokyo’s most famous Starbucks is closed

Tokyo’s most famous Starbucks is closed One Piece characters’ nationalities revealed, but fans have mixed opinions

One Piece characters’ nationalities revealed, but fans have mixed opinions We asked a Uniqlo employee what four things we should buy and their suggestions didn’t disappoint

We asked a Uniqlo employee what four things we should buy and their suggestions didn’t disappoint Princesses, fruits, and blacksmiths: Study reveals the 30 most unusual family names in Japan

Princesses, fruits, and blacksmiths: Study reveals the 30 most unusual family names in Japan One in four surveyed Japanese workers admits to wanting to kill boss, Osaka quake helps show why

One in four surveyed Japanese workers admits to wanting to kill boss, Osaka quake helps show why Tokyo’s iconic 109 department store designated most likely building to collapse in earthquake

Tokyo’s iconic 109 department store designated most likely building to collapse in earthquake Akira’s Katsuhiro Otomo to design giant mural featuring cyborg fish for Tohoku’s Sendai Airport

Akira’s Katsuhiro Otomo to design giant mural featuring cyborg fish for Tohoku’s Sendai Airport Ninja dojo opens in Tokyo’s Asakusa, offers courses in shuriken, stealth, and sensory perception

Ninja dojo opens in Tokyo’s Asakusa, offers courses in shuriken, stealth, and sensory perception We test out Uniqlo’s “new and improved” Airism mask for form, fashion, and function

We test out Uniqlo’s “new and improved” Airism mask for form, fashion, and function Man reported missing after 2011 Tohoku earthquake found alive and well

Man reported missing after 2011 Tohoku earthquake found alive and well World famous shadow artist shines a light on Tohoku relief【Art】

World famous shadow artist shines a light on Tohoku relief【Art】 Women speak out about sexual violence after Great East Japan Earthquake

Women speak out about sexual violence after Great East Japan Earthquake NHK TV worker woken by earthquake, gives viewers a show by accident

NHK TV worker woken by earthquake, gives viewers a show by accident How to put together an earthquake/typhoon preparedness kit at the 100 yen shop

How to put together an earthquake/typhoon preparedness kit at the 100 yen shop Buying property in Japan? This mini tower house can be yours for less than $12,000

Buying property in Japan? This mini tower house can be yours for less than $12,000 REVIEW: Sony’s new tablet is thinner and lighter than the iPad Air, and Android fans will love it

REVIEW: Sony’s new tablet is thinner and lighter than the iPad Air, and Android fans will love it Tokyo Fire Department uses Animal Crossing to demonstrate disaster-proof home decorating【Video】

Tokyo Fire Department uses Animal Crossing to demonstrate disaster-proof home decorating【Video】 Japanese teams use orange flags as a tsunami alert signal for swimmers and surfers

Japanese teams use orange flags as a tsunami alert signal for swimmers and surfers New “social apartment” that comes with attached movie theater will open soon in Saitama

New “social apartment” that comes with attached movie theater will open soon in Saitama

Leave a Reply